Precision Diamonds

The computerised production process guarantees an uniform distribution of a precise amount of natural diamond particles.

The diamond abrasives are available in the three different grit sizes superfine, fine, regular, coarse and supercoarse.

Six different shapes are available for minimally invasive therapy. Compared with conventional diamonds the working parts are small; the narrow and slender instrument neck allows an unimpeded view of the surface that is to be prepared.

Indication

In the dental practice

for cavity and crown preparations and for adjusting direct restorative materials

In the dental laboratory

e. g. fine adjustments to full anatomically designed occlusal surfaces on porcelain crowns, inlays, onlays and approximal areas

Range of use

Suitable for the following materials:

tooth enamel, porcelain, composites, filling materials such as GIC, cements

Benefits

exact, uniform distribution of the diamond particles

shank and working end are produced from a one-piece blank

long lasting

precision running

vibration-free action

Material properties

Working end

uniformly coated with natural diamond particles

5 grit sizes: supercoarse, coarse, standard, fine, superfine

Shapes and sizes

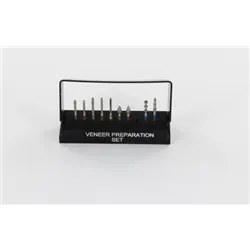

77 shapes for a wide range of preparations and procedures as well as 6 shapes for minimally invasive therapy

supercoarse grit (X, black banded): 10

coarse grit (C, green-banded shank): 6

regular (plain shank): 77

fine (F, red-banded shank): 11

superfine (V, yellow-banded shank): 19

Shank

Stainless steel shank

Working end and shank as one piece and exactly centered

Shank shapes

FG = Turbine

Recommended speed range

120,000 - 450,000 min-1

The recommended speed range varies according to the type of shank and the shape and size of the working end.

The maximum permitted speed should not be exceeded!

Note

Robot Points FG can be cleaned in an ultrasonic bath and sterilised in an autoclave.

Specificaties

| Boren | Aansluiting | FG |

| FG Boor | Dikte | 016 t/m 020 |

| Categorie | Diamant boren |